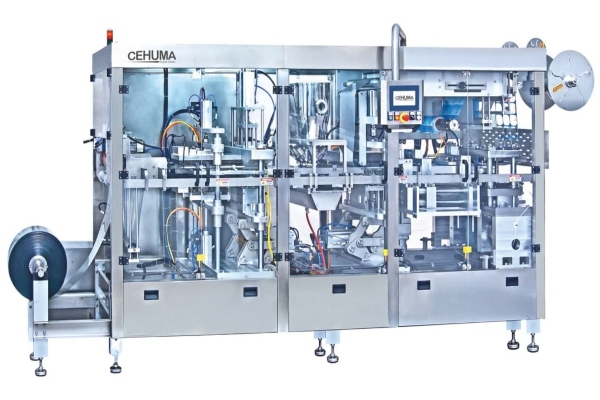

Project Description

Automatic Forming Filling and Sealing Machines (FFS).

Form Fill Seal FFS machine, YZ thermoformers are mainly for automatic form fill seal applications and very often used for filling and sealing water, juices, ketchup, mayo, honey, jam, chocolate paste, nut paste, cream cheese, coffee, milk, and yogurt. A machine is a cam-driven machine which means the plastic film forward move is done by a mechanical cam system leading to a very high output performance up 35 cycles per minute.

Technical specifications:

- Capacity (Cyc/min) | 15-35

- Index (mm) | 70-200

- Web Width (mm) | 150-500

- Bottom Web Thickness (μm) | 550-1200

- Bottom Web Material | PVC/PET/PS/PP

- Top Web Material | AL+PET

- Machine Length (mm) | 5.500-11.000

- Energy Consumption (kW) | 8-25

- Electric Supply | 3 x 380V. 50 Hz.

- Air Pressure (Bar) | 6-8

- Cooling Water (C) | 10-16

Options:

- Automatic Dosing

- Water Dosing

- Juice Dosing

- Viscous Fluids Dosing

- IP65 Level of Protection

- UV Lights Sterilization

- Hepa Filter

- CIP (Clean In Place) Integration

- Labeling Systems

Advantages:

- Entire Stainless Steel Structure

- Safety Standards According to “EC” Regulations

- Large Touch Screen

- Wide Range of Cup Design Possibilities

- Advanced Punching Technology

- Servo Technology

- Programmable Advance Speed

- Multi-language Selection

- Precise Dosing