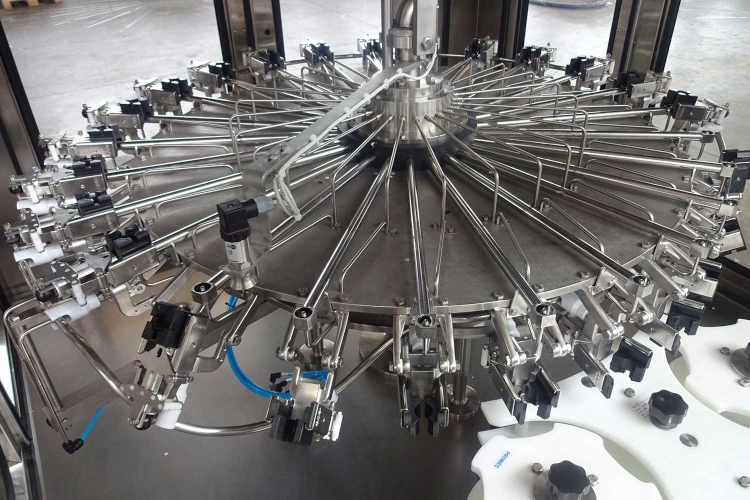

Project Description

Rinsing and blowing machine.

Thanks to the versatility of the EVOLUTION rinsing and blowing machine, Promec has developed container cleaning systems for the medical and pharmaceutical industry. For both glass and plastic bottles.

BLOWER VERSION

Firstly, the blowers are used for sensitive products that cannot tolerate the slightest residue of water in the bottle and are usually equipped with a suction system. For removing the air injected (1S+1A version). As well as a sensor to detect the effectiveness of the blowing.

Treatment times can be easily varied by adjusting the valve closing cams. For plastic bottles, Promec recommends the ionized air version, named EVOLUTION IA (IONIZED AIR). Equipped with special ionizing nozzles operating with compressed air. Which produces a high-velocity air flow that neutralizes the static charges on the internal surface of the plastic bottles while simultaneously cleaning them.

Each nozzle has an emission terminal that enables the ionizing of the air at the end of the compressed air feed pipe. Therefore around the bottle neck, by a special power supply unit. High voltage is transmitted to the emission terminals of the various ionizing nozzles that produce positive and negative ions as a result of the strong electric field generated in them.

Secondly, the compressed air which passes through the ionizing nozzles conveys the ions produced inside the bottles. Neutralizing the static charges of the opposite sign inside them. Deriving from the preparation process and from the handling and storing systems of the plastic bottles. The elimination of the electrostatic charges facilitates the removal of the contaminants (dust, paper, plastic…). Which might otherwise have remained attached to the walls of the bottles.

The action of the ions combined with the mechanical action of the air pressure help remove the impurities inside the bottles. Simultaneously with the pressurized ionized air blowing phase. An additional phase may be added, involving suction of the air injected and the removal of any dust. Creating a slight vacuum inside the bottle (version 1S+1A). This system is composed of individual annular suction units, concentric to the ionizing nozzles, and of a central manifold hooked up to a vacuum pump.

Finally with this system, the container cleaning process produces highly efficacious results. The vacuum action ensures that any impurities present inside the bottles will be removed by suction. An effect that is not normally available on normal rinsing and blowing machine.