Project Description

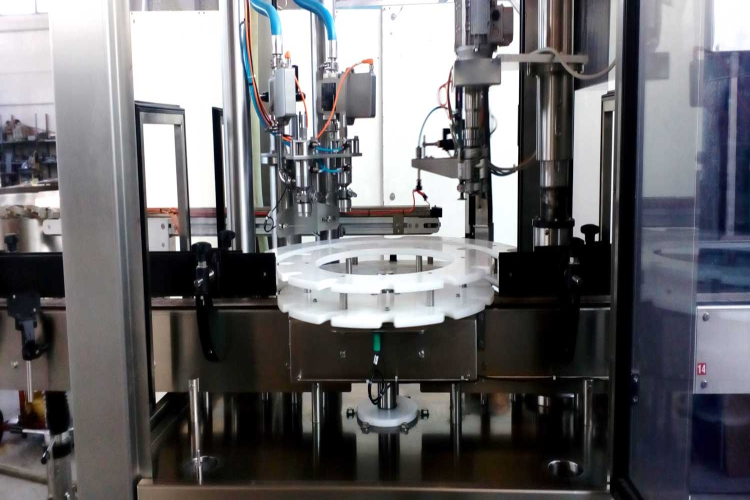

Filling And Capping Machine For Small Sizes.

FILL STAR

Firstly, this is an automatic filling and capping machine monobloc for low hourly outputs and a wide range of still products. Such as fresh or long-life fruit juices, milk, spirits and detergents.

Principle of operation:

Secondly, the filling and capping machine consists of a simple star wheel with a reciprocating motion that pulls the bottles into the different positions that correspond to the various phases:

A) The first is a volumetric filling phase in two (or more) steps, with two (or more) filling valves equipped with a magnetic or mass flow meter, to achieve gradual filling of the containers with high precision and repeatability, avoiding foam and spillage of the product from the bottles.

B) A second phase involves picking up the caps, placing them on the bottle necks and capping; all movements are sequential and managed by a system of mechanical cams.

Finally, there are different models available, with 1 to 3 filling valves for outputs up to 2,000 BPH.

Main features:

- No contact between filling valves and bottles

- Volumetric filling by means of magnetic or mass flow meters

- Extreme precision in terms of quantity bottled

- Simple filling valves with no stagnation points, easy to sanitize

- Manual dummy bottle insertion