Project Description

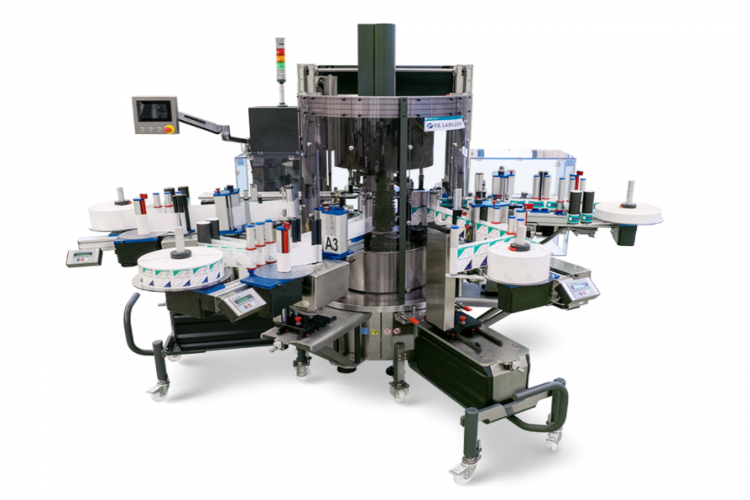

Modular Automatic Rotary Labeling Machine With Pressure Sensitive Technology and Cold Glue.

Modular CM is a completely ergonomic and modular automatic rotary labeling machine with a layout that can be reconfigured quickly and easily.

Labeling stations with pressure sensitive technology and cold glue, reciprocally interchangeable, are installed on it; they are replaceable in a few steps according to their production needs.

This machine is a compact and solid labeling solution, available in 4 sizes from small to medium, whose construction philosophy and basic features are inspired by flexibility.

The Modular CM is a machine that provides the highest standards of safety for the operators: it has up/down protections that, when raised, instantly stop the machine’s operation.

The same innovation is applied on the cold glue stations (patent pending).

The machine production speed adjusts automatically and varies according to the infeed and outfeed of containers.

Specifications:

- Production speed: 3,000 to 9,000 BpH

- Machine Ø: 480 – 576 – 768 – 960

- Plates: 4 to 10

- Technology: Pressure sensitive, cold glue

- Applications: Front and back labels, neck labels, I, L and U tax stamps, wrap-around labels

- Label material: Paper, PVC

- StationsL: Modular fixed or on cart

- Containers: Cylindrical and/or shaped

- Markets served: Wine & Spirits, Food & Dairy, Beverage

Options:

- Orientation systems with cameras, fiber optics or photocells

- Universal clamping star-wheel with bottom grip

- Pressure sensitive tax stamp and cold glue application systems

- Upside down container reading systems

- Rejection systems

- Ink-jet and/or laser markers

- Automatic format changeover adjustments with motors

- Smoothing on conveyor

- Protections

- Power conveyors

- Container storage systems

- Stop-push devices for bottles and cans

- Shaped plates

- Power slides