Project Description

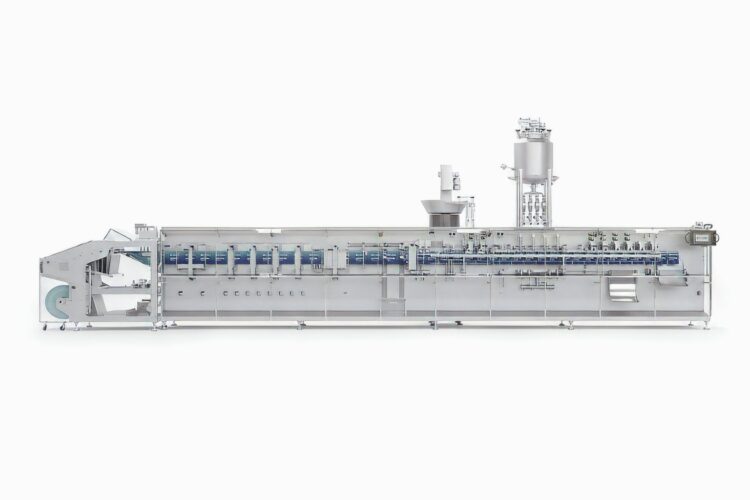

FL 2.2 / 2.6 / 3.3 Large Stand-up or Sachet Pouches w/Rollstock & Walking Beam Technology, Rollstock pouching systems, FFS Packing machine.

Rollstock Pouch Packing Machine offers all Pouch styles, The Best Option To Pack Your Product. The Smartest And Most Versatile Packaging Machines.

For those customers that require robust and versatile equipment to pack their products in stand-up pouches or big sachets, we offer our machinery series FL 2.2, 2.6 & 3.3 FFS packing Machines with walking beam technology and fast changeover. Built-in stainless Steel, all models of this series can be customized to meet specific customer’s requirements, to provide them with the most reliable equipment.

Wide format range, easy changeover, variety of filling systems and all type of fitments (spouts, zipper, shapes, etc.) can be added to this series, making them a unique and reliable packaging solution, for daily production and the most demanding packaging conditions.

They can be configurated in simplex, duplex or triplex, to achieve the desired speed up to 160 ppm, and for volumes up to 4 liters. Keeping in mind, different pouch styles and products can all be handled in the same machine.

FEATURES & BENEFITS:

Low maintenance costs and flexibility, built in stainless steel, making this series the perfect option for those clients who look for robust equipment with the latest technology and software advances (modem for remote assistance, etc.). FLtècnics offers a 3-year warranty on all of its equipment as a sign of commitment to our customers.

Automatic Splicing System

Film reel splicing system:

- Integrated to reel unwinder

- Two pneumatical reel shafts

- Rejection system for spliced pouches

- End and low reel level sensors

- Motorized reel elevator with remote control

Zipper splicing system:

- Two zipper reels

- Non-stop system

- Rejection system for spliced zipped pouches

Stroke On Demand

- Two independent main shafts driven by Servo motors

- Automatic machine start/stop system

- Filling system not ready – Machine automatic stop

- Filling system ready – Machine automatic start

- Eliminate pouch waste

Top and Corner Spout Applicator

- Independent and motorized modular spouts applicator

- Easy to adjust, during machine operation

- Corner and top spout with the same applicator

- Independent top sealers

- Spout elevator

Shaped Pouches

- Different cutting dies adapted to any shape

- Cutting die & scissors without disassembling

Ultraclean

- Hi-tech Laminar flow design

- U.V. lamps and hydrogen peroxide for film and spout decontamination

Ability to offer a variety of pouch styles and options including

- Spouts

- Zippers

- Drinking straws

- Shaped pouches

- Special applications

Filling Systems for FFS Machines:

1- Solid Filling Systems

For powders, granulates & pieces:

- Auger filler, Volumetric cup filler lineal and rotary, designed and manufactured by FLtècnics

- Multi-head & lineal weighers

- Counting filling systems

- Customized fillers for special applications

2- Liquid Filling Systems

For liquid and pasty products:

- Mass and magnetic flow meters: Endress+Hausser, Bopp & Reuther

- Piston fillers with pneumatic or servomotor operation

- Customized fillers for special applications

- Innovative system of filling correction in real time, standard on all our flow-metering dosing system