Project Description

Special Applications.

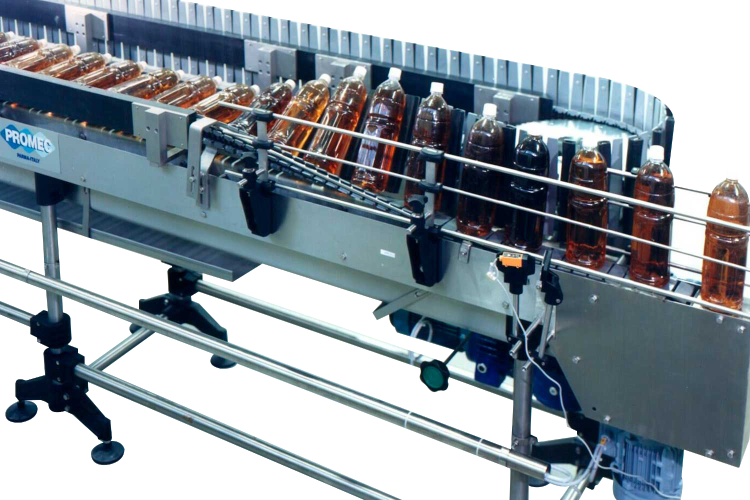

Tilting Conveyor is a unique conveyor belt to convey filled bottles and sterilize their necks by means of heat. The sterilizing machine is widely used in HOT-FILL lines. Where the product is bottled at 80 – 90 °C temperature.

The pitch-separated bottles are placed on a conveyor belt including a special articulated chain resilient to heat and tilted by 90° to the sterilizing machine. I.e. laid horizontally. Where they remain for a time sufficient to sterilize their caps (from 20 to 30 seconds).

After the sterilization stage has ended, the vertical position of the bottles is restored and they are conveyed to the packaging area.