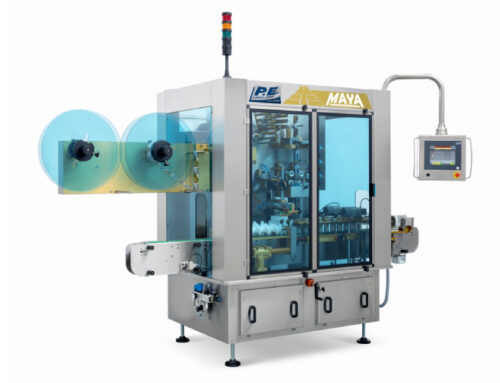

Project Description

Linerless roll-fed self-adhesive labelling machine suitable to apply wrap-around pre-glued labels.

Labelling Machine general features:

– Type: rotary roll-fed labeler

– Application: plastic pre-glued label from reel.

– Possible labelling combination on the same labeller.

– Suitable to handle cylindrical and shaped (rectangular, square, oval and so on) containers, even empty.

– Production speed from 60 to 1.000 bpm, depending on the model.

Technical features:

The two MACROPROBLEMS typical to this type of labeling machine has been eliminated in one go. Standard Roll-fed machines utilize:

HOT MELT Gluing the label edges by means of a glue roller is known to present some disadvantages:

– glue spray and relevant cleaning of the application cylinder;

– deposit of residual films or labels in the glue regulator (production stops due to cleaning operations);

– periodic cleaning of the pads during the working shifts;

– oily fumes produced by the glue heating (150°);

LABEL CUT until today, on all roll-fed machines, the label cut is performed by interaction of rotary cutting blades and one or two fixed ones. The difficulties in the adjustment of the blades during their replacement (4 to 6 hours) are well-known, as well as the production stops due to imperfect label cut.

VERSIONS

“CI” Version

Type of labelling : self-adhesive

Production speed : From 6.000 to 60.000 bph

N. of labels to be applied : 1

Label length : Up to 640mm

Containers to be handled Cylindrical – even empty

Container Ø : Max 200mm

“CR” – “SM” – “BL” Version

Type of labelling : self-adhesive

Production speed : from 7.000 to 60.000 bph

N. of labels to be applied : 1

Label length : Up to 640mm

Containers to be handled Cylindrical and shaped (rectangular, square, oval and so on) – even empty

Container Ø : Max 200mm