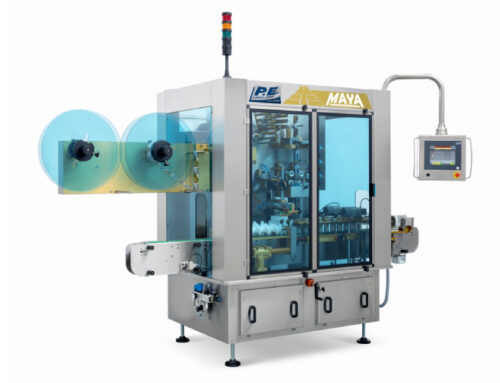

Project Description

Compact, fast change-over and versatile machine for pre-made pouches.

HFFS machine is Filling through the spout for liquid products.

Advantages of filling through the spout:

- Higher filling level in the pouch, resulting in reduced head space and reduced film waste.

- With very liquid products there is less splashing occurring.

Small footprint and high efficiency.

Food contact area: hygienic area designed for Food products applications.

Technology

- Mechanical

Mechanical technology consisting of cams.

- Walking beam

Traditional walking beam transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

- Retort

Sterilization of premade pouches and film from reel by means of an autoclave. Retort machines are suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté.

- Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

- Pre-made pouches

Option to fill the different products in pre-made pouches supplied from a pouch feeder with great capacity.