Project Description

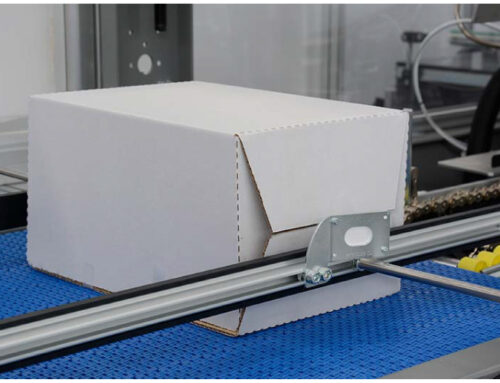

Carton Loading, Case Packing and Tray Loading machine.

Our tray loading solution is used for many products for example frozen food, breaded, coated or baked goods and chocolates or other confectioneries. It works by loading naked product into a continuously moving tray conveyor.

Our leading integrated industrial vision system takes care of positioning and orientation of the product to the robot. This may include size, shape and color inspection, depending on your needs. With high efficiency and throughput rates, so our carton, case and tray loading solutions are reputable systems that maximize your output. The solid engineering and high quality materials and parts used in its design minimize maintenance requirements and maximize continuity.

Applications

Ideal for frozen food, breaded, coated or baked goods and chocolates or other confectioneries.

The benefit

- Single pick rates of up to 120 ppm (Higher product rates with multiple pick grippers and/or multiple robots)

- Versatile: Any product count/configuration

- High efficiency and throughput

- Accepts product from bulk using proprietary BPA feeding technology

Products Handled

- Frozen food products: frozen products (including breaded or coated), baked goods, etc.

- Pouched product: condiments, sauces, entrees, single-serve pouches, juice pouches

- Chocolates and another confectionary

- Other: medical components, etc

Machine characteristics and specifications

- Dynamic loading of product into trays

- High efficiency and throughput

- Integrates to existing process

- Integrated vision

Cycle Rates

Pick & Place rates of 140+ per minute with a single robot.

Higher product rates with multiple pick grippers and/or multiple robots.

(Cycle rates are dependent upon the specifics of the application, including the ability of the product to withstand acceleration and deceleration forces, as well as size and shape of the product)

As every production environment is unique, every organization requires a tailored solution. Challenge us and put our experts to the test, to devise the solution that fits your process like a glove.