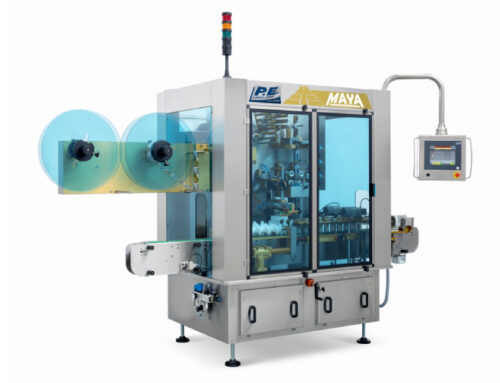

Project Description

The COMBI monobloc represents the best combination between technology, strength and reliability.

Thanks to more than twenty years of experience in the field of packaging, over time COMBI has continually obtained more and more market approval thanks to its compactness, simplicity and functionality, satisfying any type of customer request.

COMBI is a fully automatic machine, capable of working with American type of cardboard and with a large quantity of glass, PET and tin plate products.

Based on the type and geometry of the product, pick-up occurs through gripping heads, suction cups or dedicated grippers and, depending on the production speed, it is possible to have one or two pick-up heads, the cardboard box can be closed using glue or tape, in order to reach up to 1000 boxes/h

Every single movement of the machine is easily managed from the operator panel and integrated with small mechanical adjustments by specific handwheels and levers, allowing format changes in this way.

The numerous product pick-up systems designed by FIPAL over time, make it possible to adapt the COMBI monobloc to many different applications, being able to work on different types of products such as bottles, jars, cans, boxes, etc., and making this machine truly versatile.

Another feature that is also important is the aesthetic line with which FIPAL has marked this type of machine, studying a shaped structure with various tilts and including sliding doors for complete access to the inside for adjustments and/or maintenance.

Developed with the same concept of the traditional combi, FIPAL has widened the range of products that can be processed with COMBI BUS version for packaging bags in a box, keeping the same features and technologies that have already been used and consolidated.