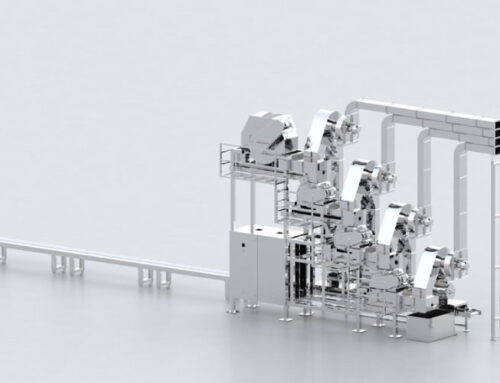

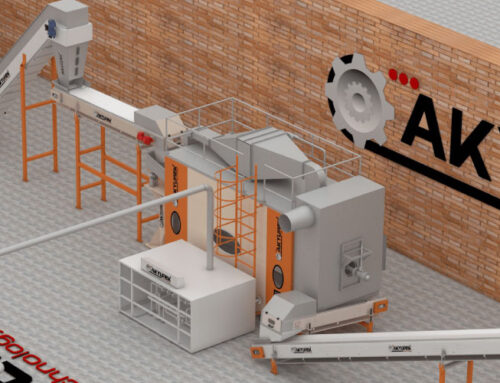

Project Description

We are offering you the best solution for Flavoring Process which is designed by highest quality R&D and produced by highest quality manufacturing.

Cylinder is manufactured by AISI 304L 1st Class Chrome, covered by 25 mm polyurethane for Heat Isolation in the Cylinder

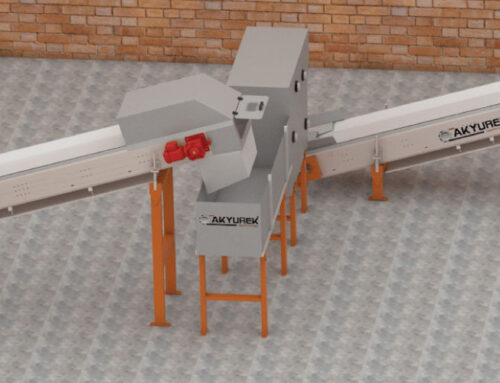

16 Conveyor Wings helps to push forward the tobacco leaves to the exit of the Cylinder.

There are 3 positions of the cylinder :

1. Steady Position: In this position, Cylinder starts to whirl around on it’s axis; at the same time cylinder’s inner heat starts to be increased by the heat changer until it gets ready for the moisturizing process.

2. Running Position: In this position, lift motors lift up the Cylinder to 2 Degrees for processing.

3. Cleaning Position: In this position, lift motors lift up the Cylinder to 4 Degrees to clean the inside of the cylinder from tobacco leaves. Inside of the Cylinder can be cleaned up with 2 nozzles easily.

There is recirculation of the heated air for energy conservation. This recirculation is provided by the help of vacuum pump, dust filter and pulse valve. Vacuum pump suck the air in the cylinder, dust filter collect the dust in the sucked air and pulse valve helps to clean the filter for prevent the clogging of the filter.

FLAVOURING TANK

All surfaces which is contaminated with tobacco leaves are manufactured by AISI 304L 1st Class Chrome

There are double jackets around the casing tank. Outmost jacket is covered by 25 mm polyurethane to avoid heat abduction. Inner jacket is filled with steam by the help of heat changer to keep the tank heat stabilized.

Mixer Motor: 0,37 KW 600 RPM

There are two mixer wings which are connected to the mixer motor for homogeneous flavouring.

There is discharge valve below the casing tank for the cleaning after the process of the batch.

There is level indicator to see and check the liquid level in the flavouring tank.