Project Description

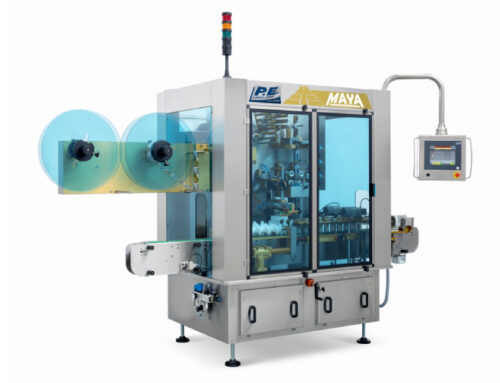

Horizontal Form Fill Seal HFFS machine, Bag-in-Box, Increasing efficiency and production flexibility, reducing cost.

The FSF Bag-in-box machine: Increasing efficiency and production flexibility, reducing cost.

The unrivalled performance, flexibility and reliability of the FSF machine, combined with excellent quality of films and fitments, empowers you to be manufacture bags more cost-effectively and of higher barrier quality.

- On-demand bag making eliminates the need for stocking one or more sku’s of pre-made bags.

- Completely automatic equipment reduces labour and maintenance costs.

- Rotary filling increases fill speeds up to four times over traditional linear filling in FSF machines.

- Two versions (single or double lines) suits different production volume requirements.

- Positive-air enclosure equipment keeps contaminants out of both bag making and filling operations.

- A specially designed cartoning system protects the bags at this critical packaging stage.

FSF equipment for liquid and semi-liquid products:

In-house, on site, in-line production and filling of bag-in-box.

Gentle filling process, the reduced amount dissolved oxygen in the bag enables longer shelf-life.

Line consists of bag-maker, taps inserter, rotary filler, carton erector, handle applying machine. All in one!

Clean-in-place (CIP) machine cycles are applicable. CIP cycle controlled by filler programming, works in-line with your existing CIP system to complete CIP circuit. This is a customer-dependent processes and can be initiated from the CIP screen. Our expert equipment field service technicians can support and maintain this filler for your continued success.

Technology

- Full servo motion

This smart servo-control system allows independent operation between the different stations, offers great reliability and little maintenance.

- Carousel

The carousel transport system patented by Bossar is the ideal technical solution for heavy and large volume packaging formats. It consists of mechanical grippers assembled on a linear carrousel with intermittent motion that hold the pouches, keeping its position during the complete filling and sealing process.

- Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

- Mirror machine

Placing one standard machine in front of the other operating the opposite direction makes operating easier and reduces staff required to control them.