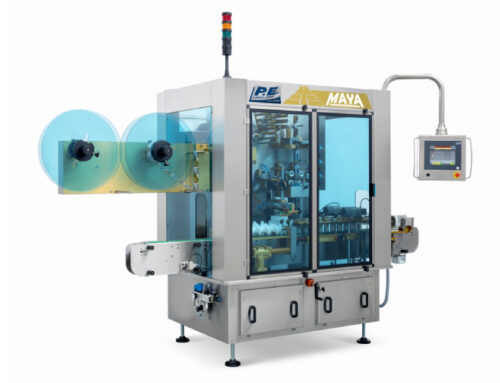

Project Description

Vertical Form Fill and Seal packaging machine (SEPP).

Features:

- Flexible: Can be built into any production line

- Perfect fit: Suited for a wide variety of film roll sizes

- Easy: Very easy to adjust and operate – even the format shoulders

Specifications:

- Up to 1800 bags per hour

- Interactive, intuitive operating software (available in a language of your choice)

- Easy-to-operate touch IPC

- Reliable, low maintenance and cost efficient

- Compact design with a small floor print

- Easy access for maintenance and cleaning

- Robust, completely stainless steel design

- Continuous supply to film buffer

- Impulse seal with film cutting blade

- Integrated film alignment (operated on the touchscreen)

Options:

- With a fixed vertical filling position (SEPP90) or with a filling position of 45°(SEPP45). A version between vertical and each position till 45° is also possible. Any inclined SEPP can always be put vertical to change the format(motor operated).

- Thermo transfer print

- Register mark control to indicate the film position

- film alignment

- Tape table for film change

- Trolley with a forklift function (to easily change the film roll and exchange parts)

- Vibrating module available (to optimize the filling of the bag)

- Module for gusseted bags