Project Description

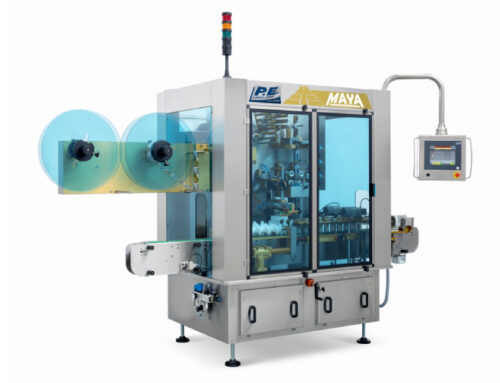

Pharma and cosmetics-oriented machinery.

Presenting the Bossar High Speed series: Pharma and cosmetics-oriented machinery.

- Low maintenance costs: Because the BHS do not require oils or greases, the maintenance time in these equipment types is considerably reduced.

- Flexibility: Optimized format change time, and possibility of working several formats on the same machine.

- Accessibility: Most adjustments are made from the screen without having to operate or manipulate mechanical parts of the machine.

- High Speed: Speed is a difference in these types of machine. Reaching a production speed of up to 300 sachets per minute.

Technology

- Full servo motion

This smart servo-control system allows independent operation between the different stations, offers great reliability and little maintenance.

- Walking beam

Traditional walking beam transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

- Retort

Sterilization of premade pouches and film from reel by means of an autoclave. Retort machines are suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté.

- Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

- Mirror machine

Placing one standard machine in front of the other operating the opposite direction makes operating easier and reduces staff required to control them.