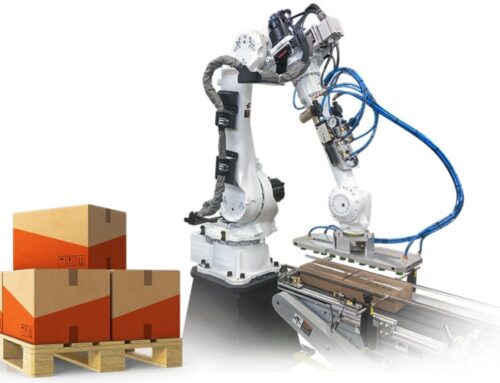

Project Description

The DYNAMIC BOX is the most innovative solution for preparing the layer of products entering the palletiser.

Suitable for any type of product, the DYNAMIC BOX is a highly performing and efficient machine designed out of the need of having a fluid, continual and fast system for preparing the layer for medium-high productions.

Currently, there are no limits for this palletisation system, as far as the type of products that can be processed since it is programmed based on the shape and size of the product and based on (any) the configuration of the layer to be palletised.

The DYNAMIC BOX is capable of managing a large amount of different formats that can be completely controlled from the operator panel and without needing mechanical adjustments, basically eliminating the format change time.

It has also been designed with modules, each of which containing a gripper. Depending on the production speed, it is possible to insert and use one to 3 grippers, having up to 3 modules in series one after the other. This way, it is possible to reach very high production speeds.

Every pneumatically controlled pick-up gripper enables rotations up to 180° in both directions, making it also possible to position the product based on label positioning.

Thanks to the great flexibility of DYNAMIC BOX, it can be used in different sectors since it is capable of handling any type of container and is therefore recommended not only for the beverage sector, but also for the chemical and food sectors. Maintenance is minimised and format change management, using the touch screen panel, makes machine use very simple and immediate.