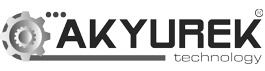

Project Description

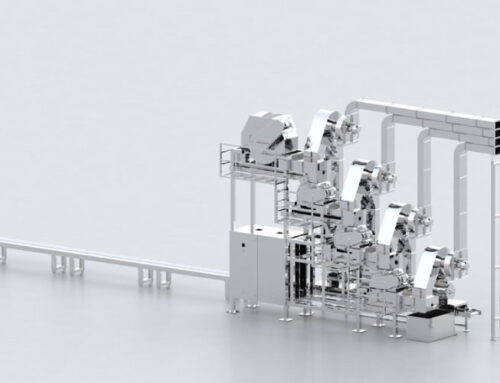

Dryer machine provides to dry the tobacco to requested moisture level up to %12.

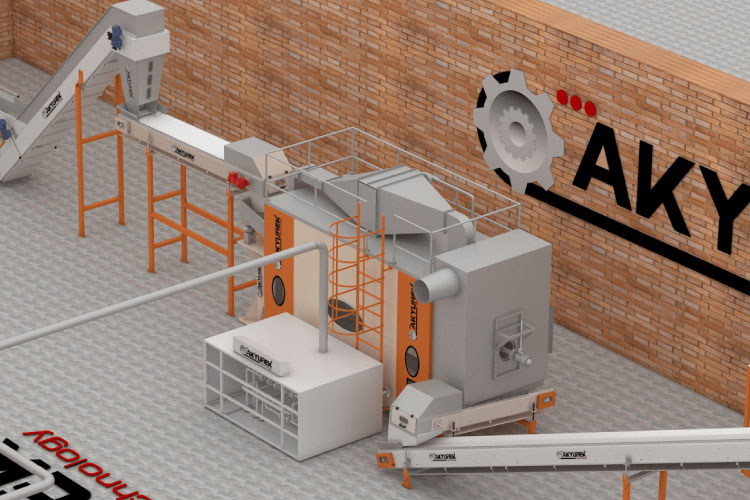

Drying Cylinder is manufactured by AISI 304L 1st Class Chrome, covered by 25 mm polyurethane for Heat Isolation in the Cylinder,

9 Conveyor Wings helps to push forward the tobacco leaves to the exit of the Cylinder. The steam in the conveyor wings provides high temperature for the wings (Up to 100 °C ).

There are 2 positions of the cylinder :

1. Steady Position: In this position, Cylinder starts to whirl around on it’s axis; at the same time cylinder’s inner heat starts to be increased by the heat changer until it gets ready for the drying process.

2. Running Position: In this position, lift motors lift up the Cylinder up to 4 Degrees (This value may change according to tobacco moisture) for drying process.

There is recirculation of the heated air for energy conservation. This re-circulation is provided by the help of vacuum pump, dust filter and pulse valve. Vacuum pump suck the air in the cylinder, dust filter collect the dust in the sucked air and pulse valve helps to clean the filter for prevent the clogging of the filter. The air comes from the cylinder is dried by dehumidification unit. Then dried air is transferred to heat changer.

According to your capacity requirement, we can offer you different capacities.