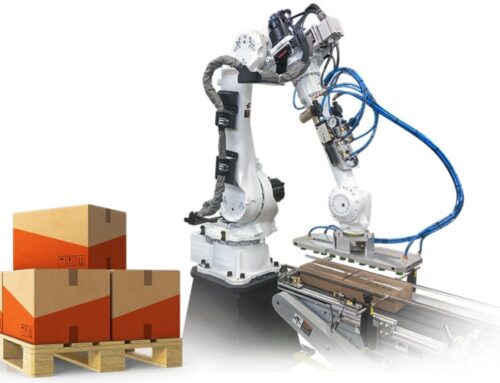

Project Description

The main characteristic of the PANTHER 200 HL can depalletiser designed by FIPAL is to have the product exiting from the top; the machine ensures production up to 60000 bph.

The operation is completed by using a booth inside of which the pallet can lift to depalletise the individual layers.

The system guarantees that it works with cans of all sizes and the machine is pre-set for quick and completely automatic format changes.

The accessories that can be inserted are:

- Empty pallet storage

- Automatic flap remover for flaps and/or pallets

- Flap storage

- Tray breaker

- Full/empty pallet motorised rollers

The system with product outfeed from the top makes it possible to reach high speeds when transferring the layers, making the operation much more simple compared to a depalletiser from the bottom since the vertical movement is managed by the containment booth where the pallet raises upwards as the layers are pulled out. This characteristic makes it possible to reach optimal efficiency and reliability.