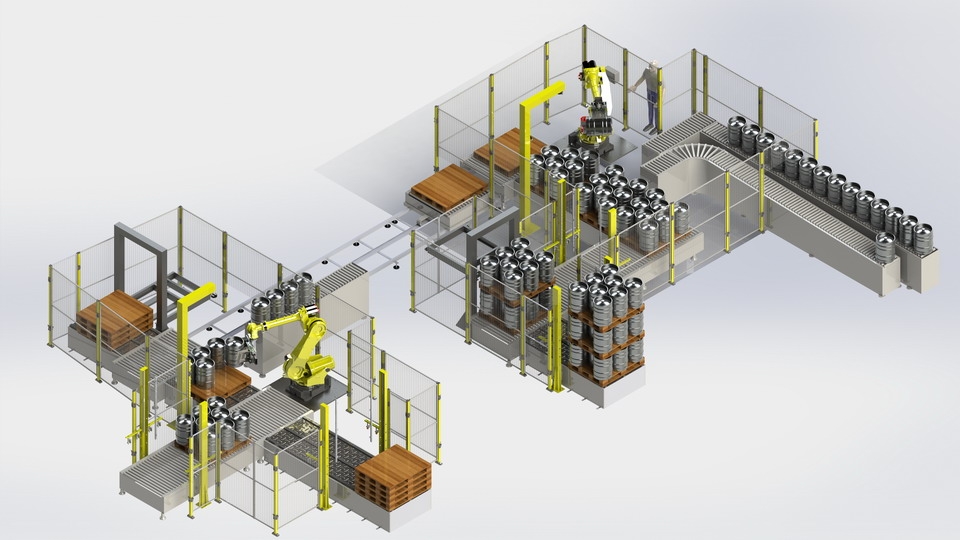

Project Description

- Secured grip of kegs

- Designed for various keg sizes

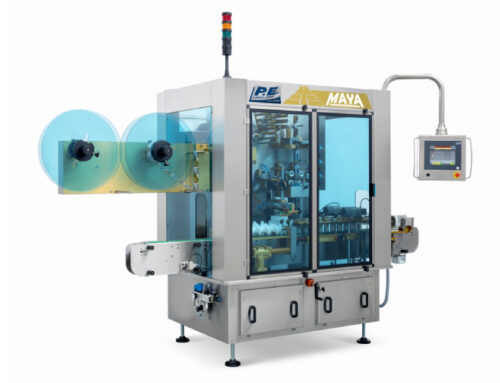

- Integration of an advanced vision system

- Vision system detecting randomly placed kegs on a pallet, keg orientation, cap presence, with optional cap removal

- Secured grip of kegs in any condition, dry, wet or frozen or partially dented

- Quick grip tooling changeover

- Power fail safe grip

- Very low maintenance

- 98.5% efficiency

- 6 Kegs/minute de-palletizing

- 10 kegs/minute palletizing

- Capability to handle empty and full kegs up to 90kg

- End effector design to handle all keg sizes: 20L, 30L Slim, 30L Large, 50L, 58L …

- 6-axis poly-articulated robot

- Manual format changeovers

- Simple drop-in piece adapts gripper to different Keg formats

- Positive grip and release detection

- User-friendly Human Machine Interface (HMI)